Key Points

- HAMR (Heat-Assisted Magnetic Recording) and MAMR (Microwave-Assisted Magnetic Recording) increase HDD storage density beyond 20TB, enabling MSPs to expand capacity while maintaining cost efficiency for large-scale data environments.

- Procurement must go beyond capacity. Evaluate workload fit, warranty, power draw, AFR, and thermal performance before purchase, and always pilot test new drive generations for compatibility, rebuild behavior, and stability.

- Validate platform and thermal readiness by confirming controller firmware support, testing backplane vibration limits, and ensuring chassis airflow, PSU margin, and cooling can sustain HAMR/MAMR drive thermals under full load.

- Design tiered storage strategies that match data temperature and cost goals. Use SSDs for hot data, traditional HDDs for warm tiers, and HAMR/MAMR drives for cold or archive tiers with RAID 6 or erasure coding for data protection.

- Implement proactive monitoring and firmware governance using dashboards that track SMART metrics, temperature, latency, and rebuild times; standardize firmware rollouts and create a preventive maintenance cycle.

- Prove recoverability and manage lifecycle risks with 3-2-1 backups, immutable storage, regular restore drills, and diversified vendor mixes to minimize correlated failures and supply-chain delays.

HAMR and MAMR can increase the data capacity of your HDD drives. As an MSP, it’s crucial to know how to buy, rack, monitor, and back up these drives so they can deliver what you need without compromising uptime or restores.

A guide for planning for HAMR and MAMR drives in MSP environments

📌Prerequisites:

- You need to have a target capacity plan (per client) with RPO/RTO, hot/warm/cold tiers.

- You should have a list of qualified chassis/backplane/HBA for drives that can host more than 20TB. It should also contain vibration specs.

- You need to know your environmental baselines (rack airflow, inlet temps, PSU margin)

- You need a monitoring platform that tracks SMART, temps, firmware, and latency.

- You should have a backup platform with immutable/object-lock and routine restore drills.

Step 1: Set procurement criteria beyond capacity

There are many options out there, and both HAMR and MAMR drive sellers want to get your business. Because of this, you should be mindful when choosing. Don’t just go off what marketing tells you. Do your research and choose a drive that will fit into your operational workflow.

To do that, you must:

- Define your per-workload needs (backup/archival, video, object storage, general NAS).

- Compare the HAMR and MAMR options available on warranty (yrs/ DWPD-like limits), AFR, workload rating (TB/yr), power/heat, and vendor supply outlook.

- Run a pilot test on at least one shelf per platform before making a large purchase—record temperatures, acoustics, and rebuild times.

Once you’ve collected all this information, you should end up with a data-driven shortlist that fits your organization’s workloads, SLAs, and thermal budgets.

Step 2: Validate platform and thermal compatibility

When choosing between an HAMR and MAMR drive, the hardware itself is important. Some drives will work better in certain environments. To avoid silent instability, you need to know the drive’s chassis/backplane limits.

To determine if an HAMR or MAMR drive fits your current setup, do the following:

- Confirm that the controller firmware and expander/backplane have support for more than 20TB. This ensures it can handle all the data your organization processes.

- Measure the inlet/exhaust temps, set fan curves, and test drive-to-drive vibration.

- Perform a stress test for rebuilds and scrubs during peak thermal load.

If you do your testing properly, you should end up with stable shelves that keep energy-assisted drives within spec under real load.

Step 3: Build a tiered data placement strategy

HAMR and MAMR drives have different strengths. Use the right medium for the right data to ensure that your setup is properly optimized and working at its best.

For example, you can

- Place hot data (data that you need to access often and immediately) on SSD (NVMe/SAS), warm data (data you need to access less frequently) on mid-capacity HDD, cold data (backup or archived data) on HAMR/MAMR drives.

- Enable erasure coding/RAID tuned for rebuild time (e.g., dual parity); regularly schedule scrubs.

- Document Object Lock/immutable retention for backups on HDD tiers.

Doing these things will give you predictable performance, protected recoverability, and a low cost per TB ratio.

Step 4: Raise monitoring and firmware standards

Once you’ve set up your HAMR and MAMR drives, you need to keep them functioning properly. To protect your organization’s data, you need to catch degradation early and prevent firmware surprises.

Some steps you can take:

- Track information like temperature, SMART parameters, write/read latency, and lifetime TB written; alert on trend slopes.

- Standardize firmware levels, stage upgrades in a pilot set, then roll out with maintenance windows.

- Log rebuild duration and scrub error rates for capacity planning.

You need to create a preventive maintenance loop. This reduces data-risk windows and ensures that you won’t lose critical information.

Step 5: Prove backup and restore readiness

Having the correct drives for all your data isn’t enough. You also need to ensure that these drives are ready for data backup and restoration.

Here are a few steps you can take:

- Stick to the 3-2-1 backup rule with at least one immutable copy

- Test restores monthly: latest point and a mid-chain backup; record RTO and throughput

- Document URE tolerance (e.g., RAID level vs. drive size) and ensure rebuild times don’t exceed risk policy

Step 6: Govern lifecycle and vendor mix

Reduce correlated failure risk and supply constraints by keeping an eye out for the lifecycle of your HARM and MAMR drives and ensuring that interactions with your vendors remain optimal.

To do that, you should:

- Diversify vendors/series across shelves to minimize batch correlation

- Rotate drives on staggered lifecycle

- Maintain a sparing policy sized to rebuild times and supply chain lead time

What are HAMR and MAMR drives?

You can greatly increase the amount of data that can be stored in an HDD by temporarily heating the disk as you’re writing on it. HAMR and MAMR are two different ways of doing this. Here are their key differences:

HAMR

HAMR stands for heat-assisted magnetic recording. It uses laser-powered heat on the HDD to reduce its magnetic hardness, which in turn makes it more receptive to magnetic effects and allows for writing on much smaller sections of the drive.

MAMR

Microwave-Assisted Magnetic Recording (MAMR) uses a spin torque oscillator (STO) to generate microwave fields, which are then directed to the disk. This lowers the disk’s resistance, meaning that the writer head can more easily alter the magnetic orientation of the bits. This means that the HDD can have a higher storage density without requiring the extreme heat used in HAMR.

NinjaOne integration ideas for planning for an HAMR or MAMR drive

- Inventory and Tagging: Auto-tag by capacity/series (HAMR/MAMR), shelf, and role (backup/archive/object).

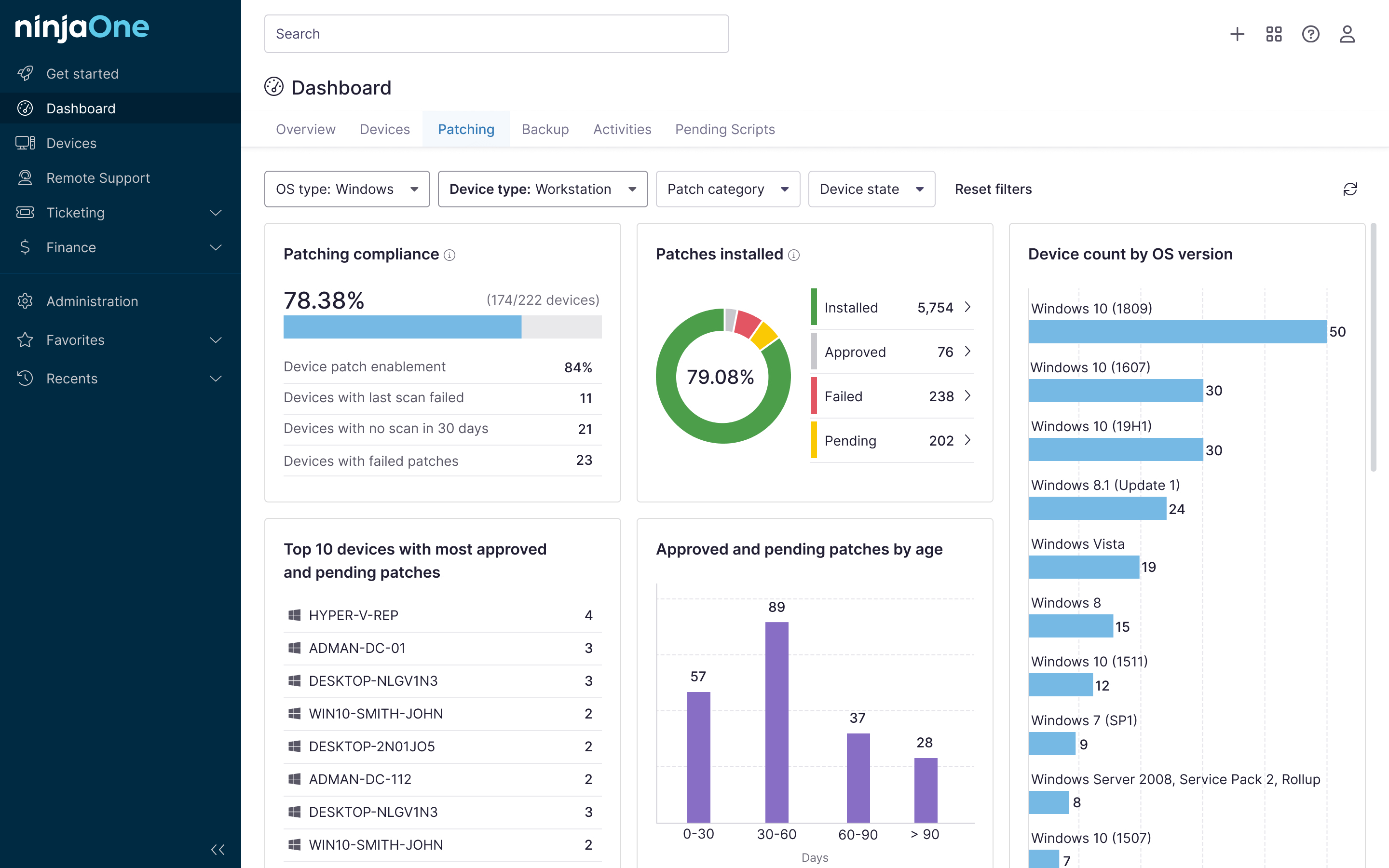

- Monitoring: Dashboards for temps, SMART trends, rebuild timers, and firmware drift; threshold-based ticketing.

- Automation: Scheduled health reports, firmware pre-checks, and post-upgrade validation scripts.

- Evidence: Store restore drill logs, rebuild metrics, and QBR capacity plans in Docs for auditability.

Increase your data storage capacity with MAMR and HAMR drives

HAMR and MAMR allow your organization to store more data in HDD drives. Make sure that your decisions are anchored in workload fit, thermals, monitoring, and backup discipline. Keep your drive shelves cool, firmware steady, and data restores fast to ensure that you make the most out of your investments.

Related topics: